I joined the Rutgers ARM team in January 2015. The team was to participate in the first Amazon Picking Challenge in June 2015.

The team wanted to explore grasp validation using vacuum sensors.

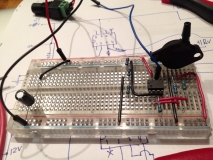

In my younger years when I spent a lot of my time modifying cars, engine tuning, turbocharging, etc., I remember people often used GM 3-bar MAP sensors together with MEGASQUIRT engine management, because they were cheap and reliable. Before shelling out money for expensive vacuum sensors I decided to give it a try (I was also itching to design my own circuit, which I hadn’t done in a while).

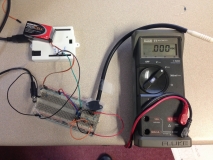

The sensor I used was the MPX2100AP (click for datasheet). The sensor was to be powered by a 12V AC/DC converter and the measurements read by an Arduino. Overall the sensor was not a good match for our application, since most of readings fell in a very narrow band of the sensor’s working range. That combined with the Arduino’s relatively poor 10-bit ADC, meant we had very poor resolution (even after adding an OP-AMP to the circuit).

Even though the sensor was not used for the application we intended, it was a fun technical exercise and it is ready to be used in other projects.

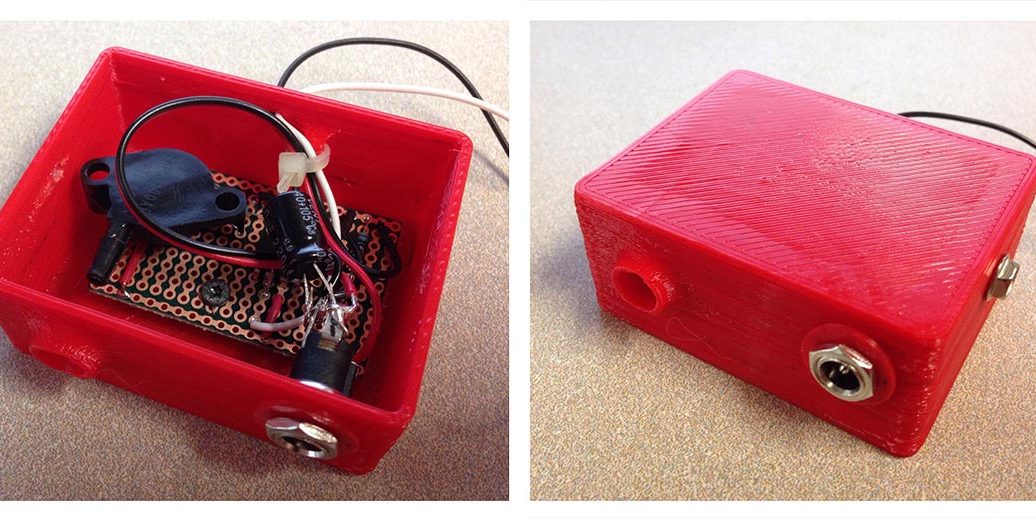

The entire circuit was tightly packed in a 3D printed enclosure and the Arduino UNO replaced by a much smaller Arduino Pro.