I joined the Rutgers ARM team in January 2015. The team was to participate in the first Amazon Picking Challenge in June 2015.

The team had been collaborating with Unigripper, Sweden, and had received a 1-DoF vacuum gripper, featuring Unigripper’s patented technology, which consists of multiple holes and vacuum foam. The technology’s main advantage is the ability to attach to uneven surfaces and have minimal vacuum losses through the holes which are not closed by a surface.

The team had been collaborating with Unigripper, Sweden, and had received a 1-DoF vacuum gripper, featuring Unigripper’s patented technology, which consists of multiple holes and vacuum foam. The technology’s main advantage is the ability to attach to uneven surfaces and have minimal vacuum losses through the holes which are not closed by a surface.

While the technology works well in industrial settings the lifting force was often insufficient and the gripper was very bulky, which is a big problem when picking in clutter.

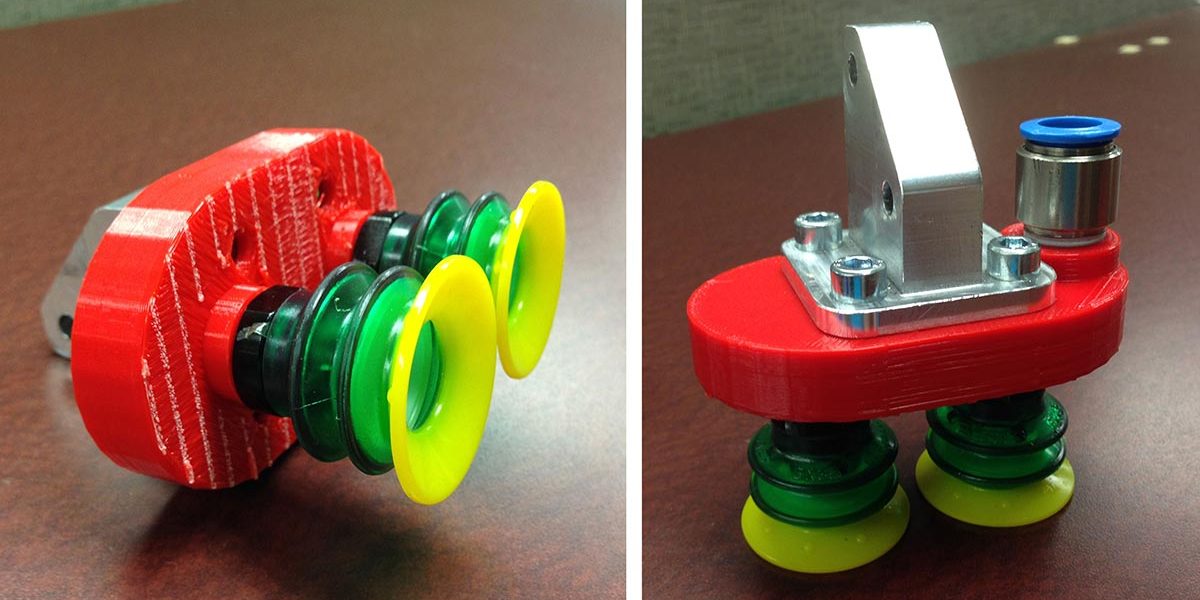

Shortly before the competition, I was tasked with designing and fabricating a simpler, smaller attachment for the end of the gripper, using one or more suction cups. It was to replace the Unigripper box.

I designed a simple attachment with pre-threaded holes to accept 2x28mm PiAB suction cups and 12mm air tube quick-connector. It also featured M6 hex nuts embedded into the print, for secure mounting to the metal arm.

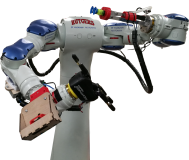

The overall size of the gripper was greatly reduced and it was one of the 2 grippers used in the actual competition. It was precise and offered great lifting force and overall performed great.

Amazon Picking Challenge 2016 Demo (Grippy used for second year in a row, mounted on the left hand)